Baseload Electricity & District Heating

Geothermal tremendous untapped reserves

Our planet has a sun inside

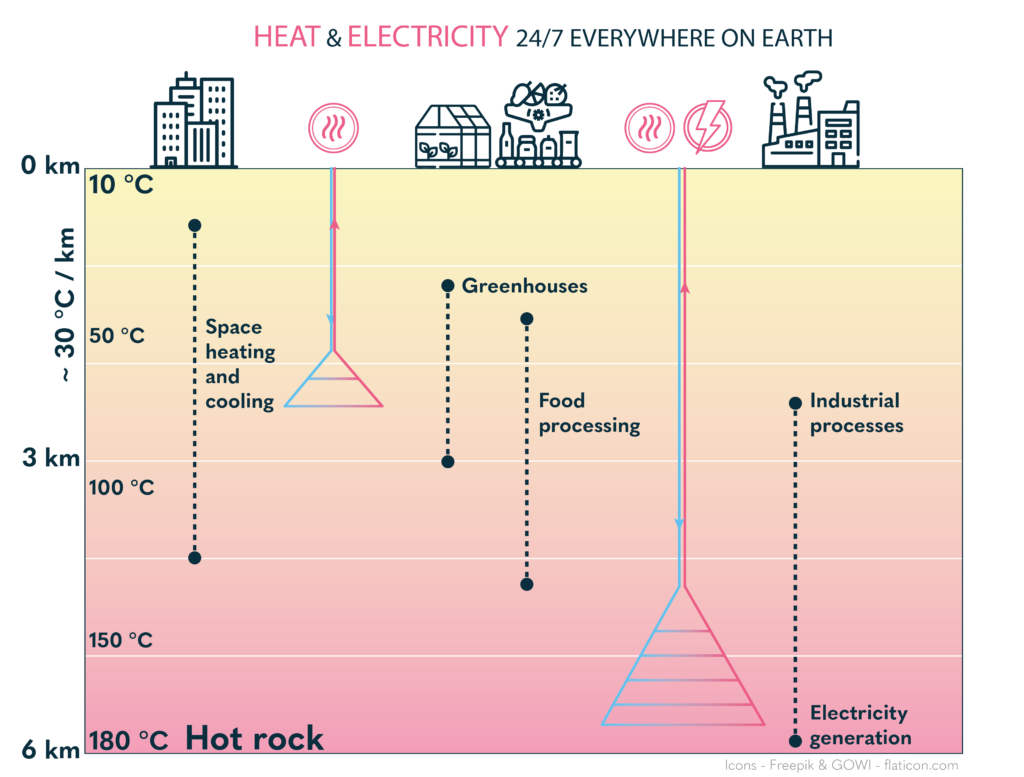

AGS are closed-loop deep geothermal installations that tap into the largest planetary energy source: the heat of the Earth, stored anywhere in deep rock layers, just below our feet.

Unlike conventional hydrothermal or Enhanced Geothermal Systems (EGS), AGS do not produce brines from a hydrothermal or engineered geothermal reservoir but instead circulate a working fluid through sealed boreholes to recover the heat from deep hot rock layers.

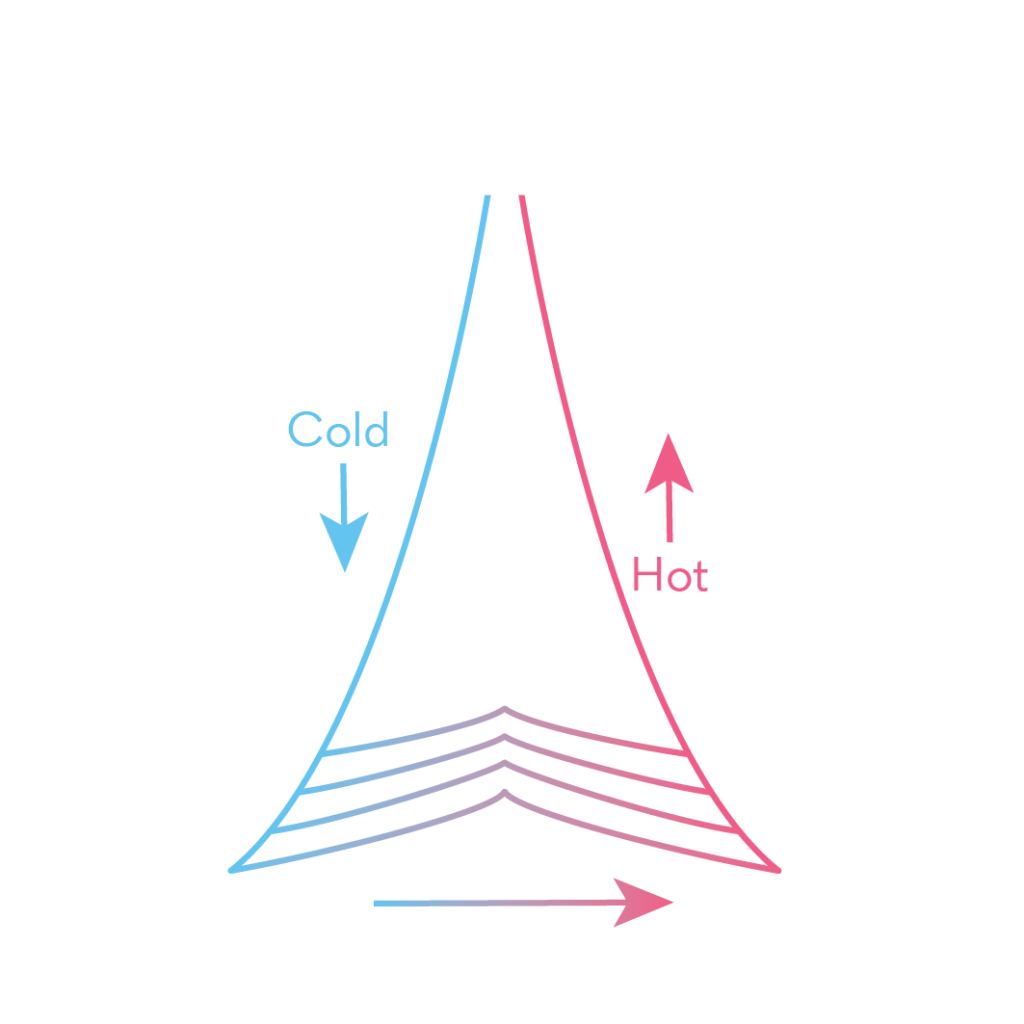

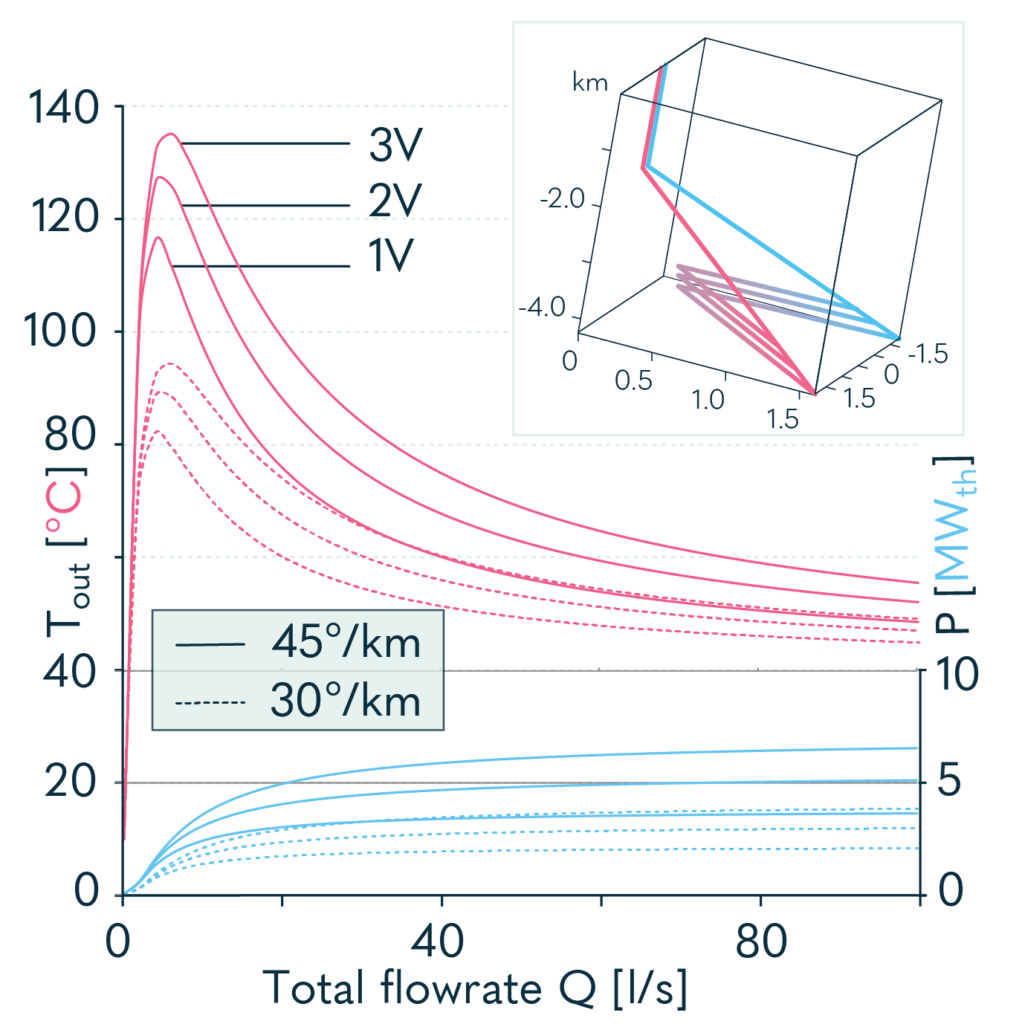

AGS are purely conductive systems: the power capacity of the installation depends directly on the length of the heat collection well(s) at depth.

Building upon recent development honed by the oil and gas drilling industry in directional drilling and magnetic ranging solutions for well intersection, it is possible today to build AGS radiator-like installations, circulating a working fluid in series of deep boreholes loops deployed between an injection and a production well.

EAPOSYS AGS delivers long-term energy in the form of heating and baseload electricity at the community level (a few MW thermal per installation unit).

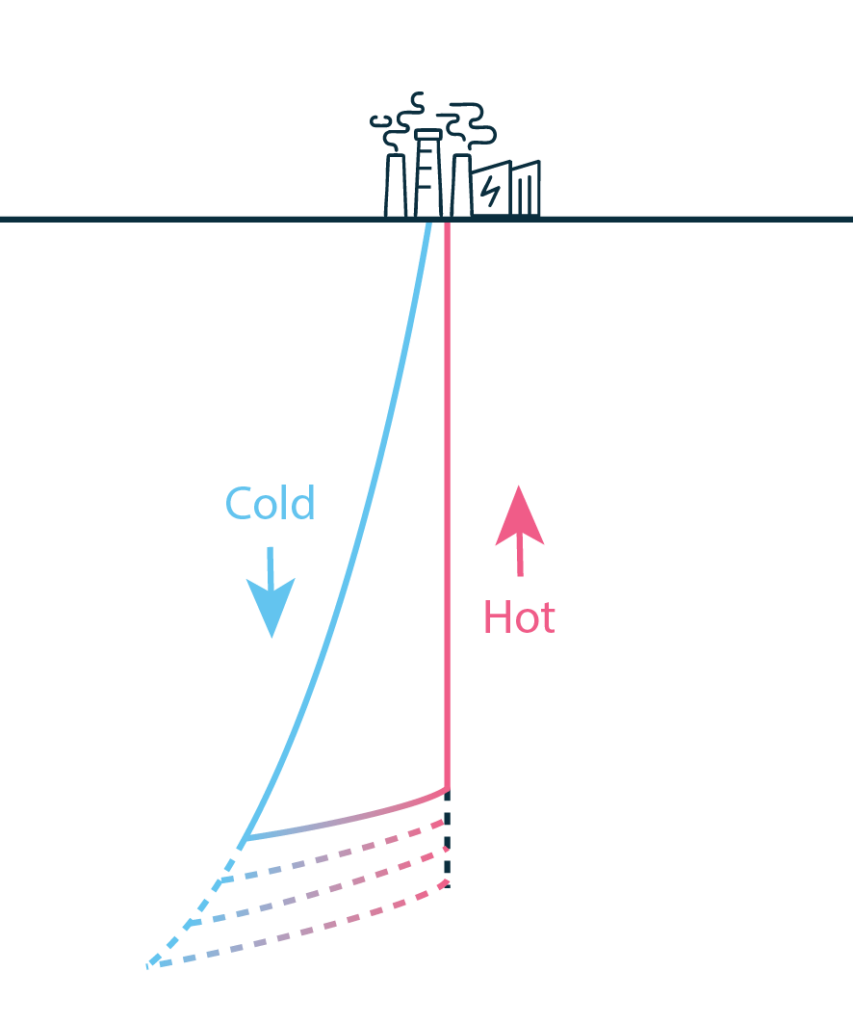

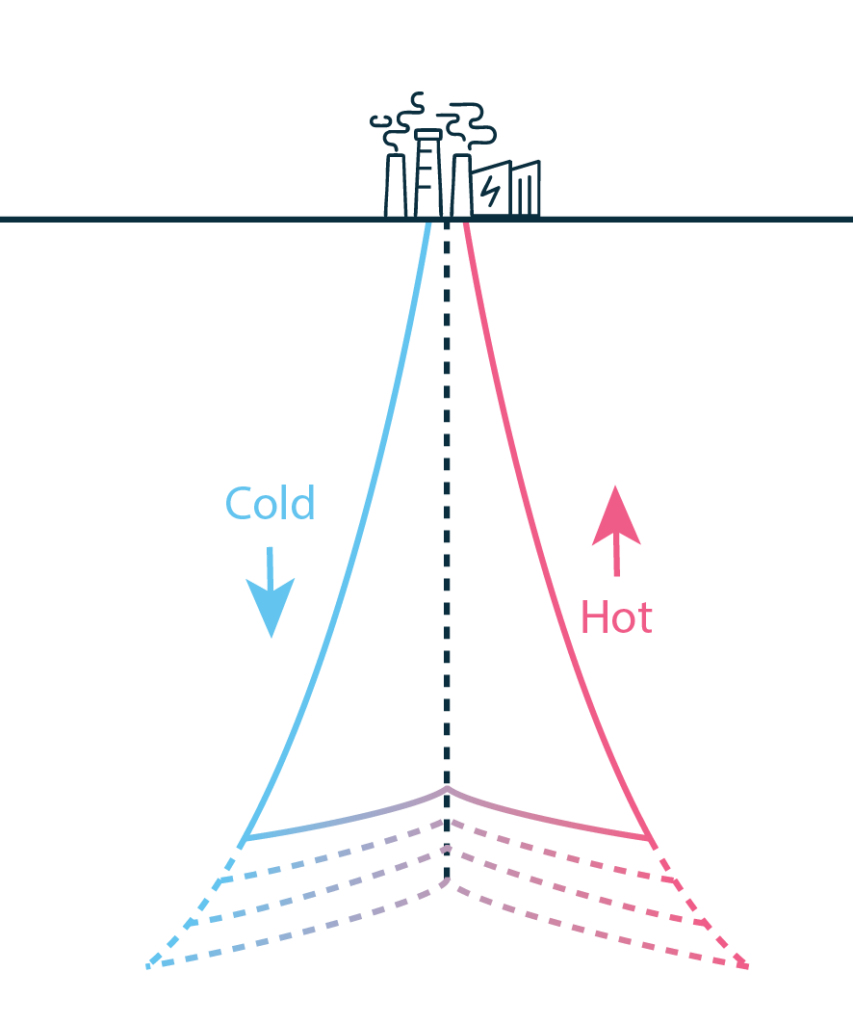

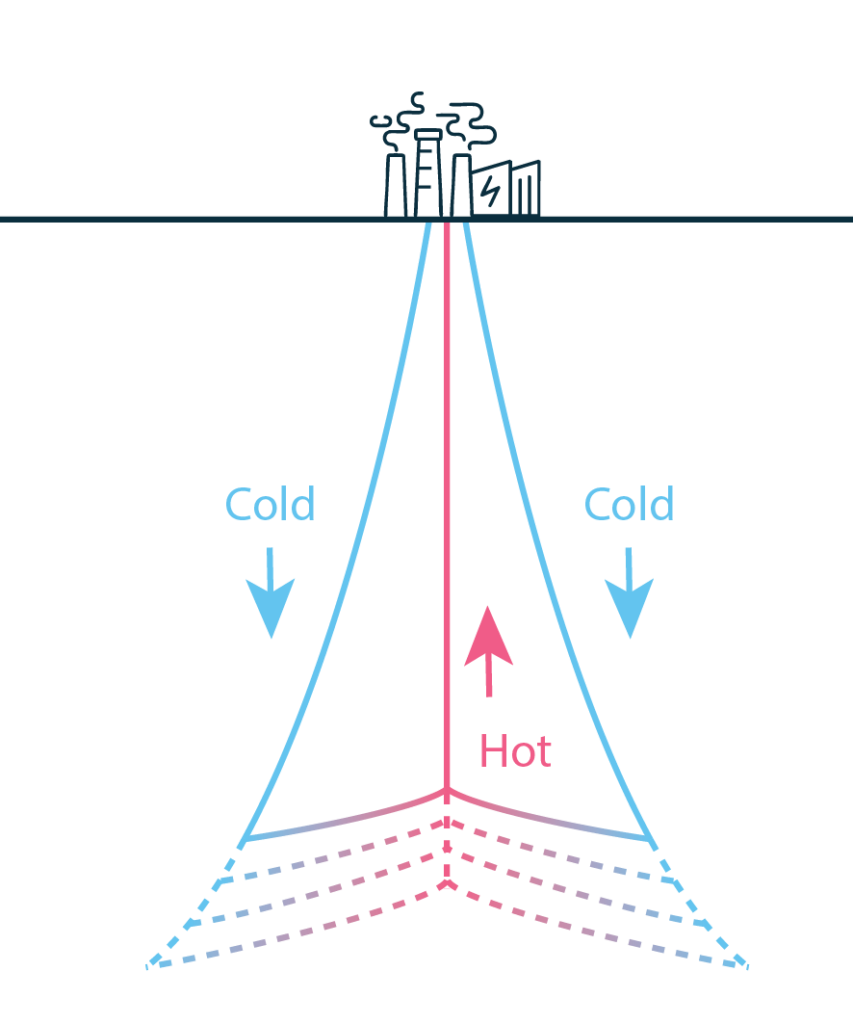

The unique feature of EAPOSYS AGS lies in our patented service well that enables an incremental, butterfly-shaped deployment of the installation across the targeted heat depth sections.

Once the injection well (blue, for cold fluid distribution) and production well (pink, for hot fluid collection) have been completed, the horizontal well sections are drilled from the service well (dashed black) and connected to the injection/production wells to create EAPOLAPs heat recovery conduits linking together the injection and production wells in a circular closed loop.

EAPOSYS Patented Service Well USP

Incremental deployment

Butterfly-shaped geometry

Minimal

Incremental

Optimized

EAPOSIM: E.AGS Simulation Software

EAPOSIM consists of an initial software kernel enabling rapid calculation of E.AGS installations energy output.

This initial analytical calculation module allows the treatment of multiple wellbore sections along any pre-defined polygonal line geometries and parameters in a vertically linear geothermal gradient field. The module is developed by Prof Pierre Perrochet at the Center of Hydrogeology and Geothermics (CHYN) of the University of Neuchâtel.

Energy output results over time as a function of applied flow rate and injection temperature are available at the click, allowing for the rapid development of various usage scenarios and their associated configurations.

| Privacy Policy | Terms & Conditions | Cookies policy

All content © except otherwise specified. All content done for other companies are copyright of their respective owners.

EAPOSYS SA

Schwadernauweg 33

CH-2504 Biel/Bienne

Web development | Metamorphe